Renovation of a Wooden House 03

In this article, we would like to show you how to plan for and get the best out of thermal insulation in wooden houses.

The house is south-facing and sunny, but there was no insulation in place. The windows were aluminium sashes, and the walls and floors were not airtight. So the airtightness of the building was not measurable, which is normal for a house built in 1975. As it was our intention to renew the external walls, flooring and finishes, we thought it would be a good idea to take the opportunity to add some insulation. So we proposed the insulation to the client and got his approval. (However, due to budget constraints, we decided to insulate the main part of the ground floor rather than the whole building.)

In order to improve the thermal insulation of a house, we try to wrap the subfloor or the foundation, the exterior walls, the roof or the ceiling with materials that do not easily transfer heat. This is like wearing a feather down jacket when walking in the mountains with snow.

Another thing that is needed is to wrap the space with materials that does not allow the wind to blow. If you are walking in the mountains with snow and you are sitting still during a break, you will get cold in a strong wind. So, it is necessary to wear a down jacket and other windproof clothing to keep the body warm. The same applies to the insulation of a house, which in architectural terms is called “airtightening”.

In a reinforced concrete apartment building, the concrete is poured and the sashes are installed, creating a space with very few gaps for air to pass through.

In contrast, traditional Japanese wooden houses are built on a frame of timber, to which boards are attached to create a surface, resulting in a structure with many gaps. This leads to the need to fill in the gaps and, in some cases, to work in detail.

The first step in this project was to determine the area to be insulated, determine the method and specification of the insulation, calculate the energy consumption and determine the details of the insulation work. The method used was to spray urethane insulation on the external walls and the ground floor ceiling, and to install a moulded phenolic foam under the floor. The thickness of the polyurethane foam in the exterior walls is 8 cm, and that in the ground floor ceiling is 20 cm. The thickness of the phenolic foam under the floor is 6cm.

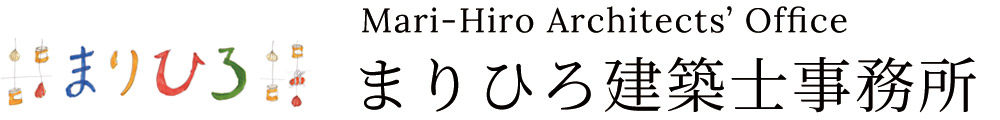

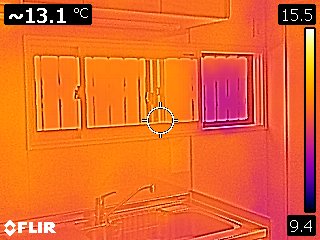

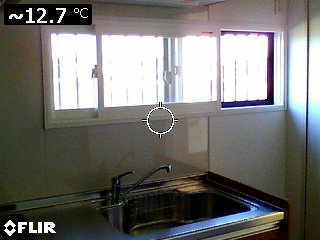

The windows are made of aluminium (paired glass) on the outside and plastic (also paired glass) on the inside, with a layer of air between them.

These four pictures show the difference in surface temperature between the front of the renovated kitchen, with the internal window slightly open, and with it closed. The aluminium sash on the outside transfers heat easily, so the surface temperature is the same as the outside temperature, but the air layer and the plastic inner window itself are less sensitive to heat transfer, which helps to keep the warm air inside.

As a result, the annual energy consumption for heating and cooling in this house (insulation area only) is calculated to be 10.85 GJ for heating and 5.68 GJ for cooling in terms of gigajoules.

Gigajoules may not give you a clear picture, so let’s try to convert it into the image of paraffin. If we convert the amount of energy required for heating in one year into paraffin, we see that it is 6.7 litres per square metre of floor space. This is based on the assumption that the room temperature in the insulated area is kept above 20°C during heating and that the heating is left on 24 hours a day, every day, without a break during the winter. (20°C is a comfortable and healthy room temperature.) In this case, the floor area of the insulated area is 43.889 square metres, so the energy required to heat the entire insulated area is calculated to be the equivalent of 296 litres of paraffin. (At the current market price of paraffin in Tokyo on 1 March 2021, this would be 27,800 yen).

The house has an average thermal envelope “UA value” of 0.366, which is a commonly used index in Japan. On the other hand, the Japanese government’s recommended value (for the Tokyo region) is 0.87. Unfortunately, this is not a desirable value for thermal insulation, but it is included here for comparison. The lower the “UA value”, the better the performance, which means that this house is 2.37 times better insulated than the Japanese government’s recommended standard as of 1 March 2021.

In addition, the airtightness of this house, which is the “windproof material clothing” mentioned earlier, was measured to be 2.0 (area of gaps in square centimetres per square metre of floor space). This is an excellent result for a renovated wooden house.

In fact, when you heat a room in this house with an electric hot-air heater or an oil heater, the room warms up easily and you don’t feel any cold air near the windows.

Thus, by making the insulation and airtightness as high as possible, we have been able to contribute to reducing the environmental impact, lowering energy costs and ensuring the safety of the residents, without any health problems caused by the cold.

To read the previous article, please click here.

Read about our achievements: Renovation of the entire reinforced concrete apartment building

Read about our achievements: Renovation of a single unit in an apartment building

Read about our self-introduction: Mari-Hiro Architects’ Office